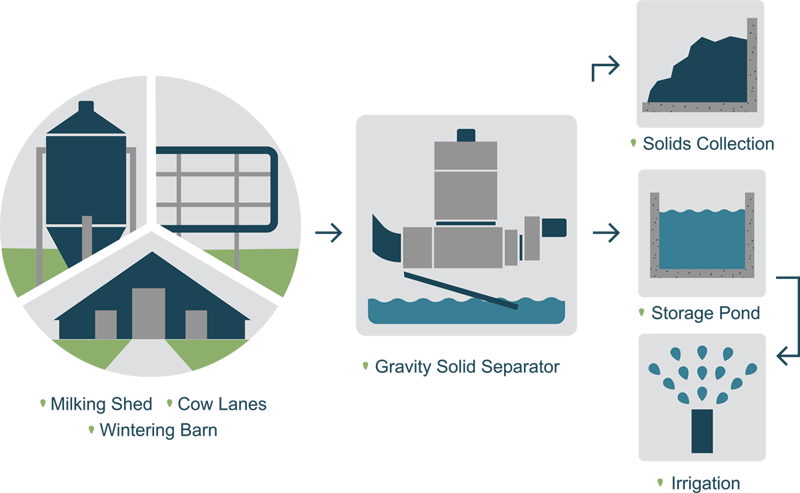

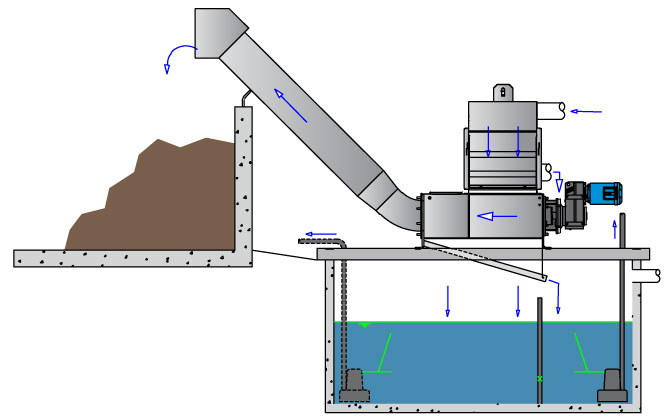

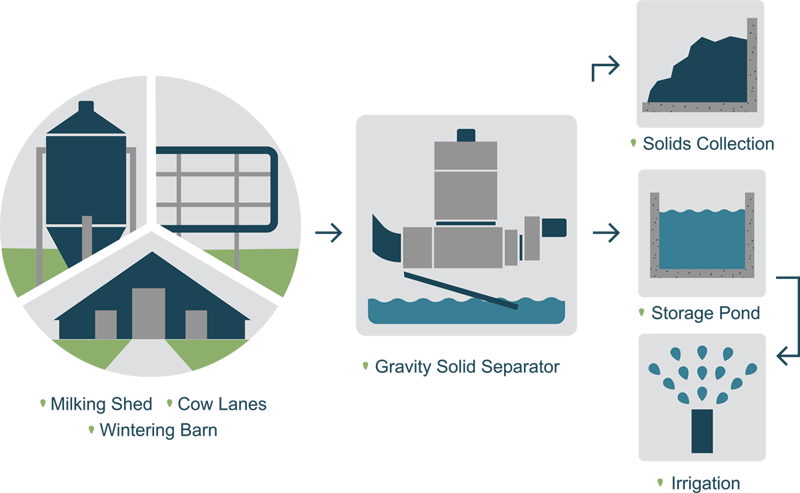

The GRAVITY Solids Separator (patent pending) is an integrated solids dewatering and removal system and can be adapted to new or existing dairy milking sheds, feed pads or wintering barns. It is designed to function with multiple effluent inlet connections, such as from the yard, shed, tanker pad and various wash down methods. These areas are piped by gravity to the Solids Separator that is supported above a concrete holding tank. The effluent passes through the surge manifold and over the inlet screen which feature our ‘flow enhancement deflectors’ for gross dewatering, this removes large volumes of liquor that is expelled directly into the holding tank.

The residue liquid and solids fall into the press chamber for further dewatering and compression. The press operates on demand and actuated by a shielded level sensor. This intermittent operation reduces energy usage and keeps wear and tear to a minimum. Compressed liquor falls into the holding tank and compacted solids are elevated by force through the solids discharge flume achieving a high degree of compression. These compressed solids fall from the flume onto a concrete pad or vehicle by the introduction of new effluent at the beginning of the press. The compressed solids can then be redistributed over paddocks, landfall or burnt as fuel.

The baffled holding tank enables the initial screened liquor to be reintroduce to the system by way of the recycle pump which in turn provides finer separation. The holding tank water levels are controlled by a second submersible pump that discharges to the storage or irrigators.